|

Spring | Productions |

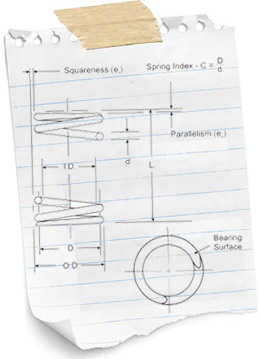

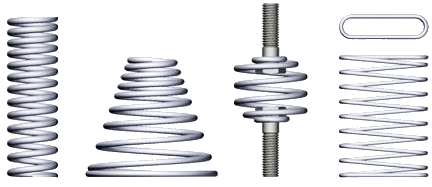

Mechanical springs come in a wide variety of sizes, shapes and materials. Compression, extension, torsion, constant force and Belleville springs are commonly used by manufacturers. Each type of spring presents unique challenges to automated assembly systems. In addition to shape, the type of material that a spring is made out of can affect automation. For instance, springs made from softer materials, such as copper, can act differently than harder materials, such a stainless steel.

Phisical Objectives

Physical Strength of the springs is directly dependent on their Strength ratio indicated by (K) technically speaking (k) is only constant as long as the (d) also known as distance varies wityhin the newton distance.

Strength of materials

One of the most important variables to be considered closely and can intensify the critical point is for sure the material used to produce the springs .

Compression Springs

|

In order to propegate The load over a surface Sometimes using this kind of spring is inevitable. |

Torsion Springs

|

Rotational loads must be balanced where necessary thats the reason why we utelize this kind of spring . |